Basic Info.

Model NO.

RAY-XS014#

Material

Optical Glass

Lenses Color

Clear

Certification

RoHS, ISO9001, CE

Customized

Customized

Coating

Vis-Nir Coated

Transport Package

Cartons or Wood Case

Specification

2-75mm or custom manufacturing

Trademark

Raytek

Origin

China

HS Code

9002909090

Production Capacity

100000PCS Per Year

Product Description

General Introduction:

Achromatic lens is made by gluing two single lenses. The product is optimized by computer to reduce the spherical aberration and chromatic aberration on the axis. Single layer MgF2 film or broadband antireflection film can be selected. NIR achromatic double glued lens and edge blackening version can also be selected. All dimensions are in mm.

The performance of achromatic lens in multicolor (white light) imaging is much better than that of single lens. This product is glued together by two lenses of different materials (literally "lenses without chromatic aberration") to correct the dispersion of the glass. The achromatic lens is widely used in multi-color lighting and imaging, which improves the cost-effectiveness.

Products Name: VIS Coated Achromatic Lenses

Alias: VIScoating achromatic Lenses, achromatic lens with VIS 0° coating, 4λ achromatic lens, VIS 0° achromatic Lenses

Products Highlights:

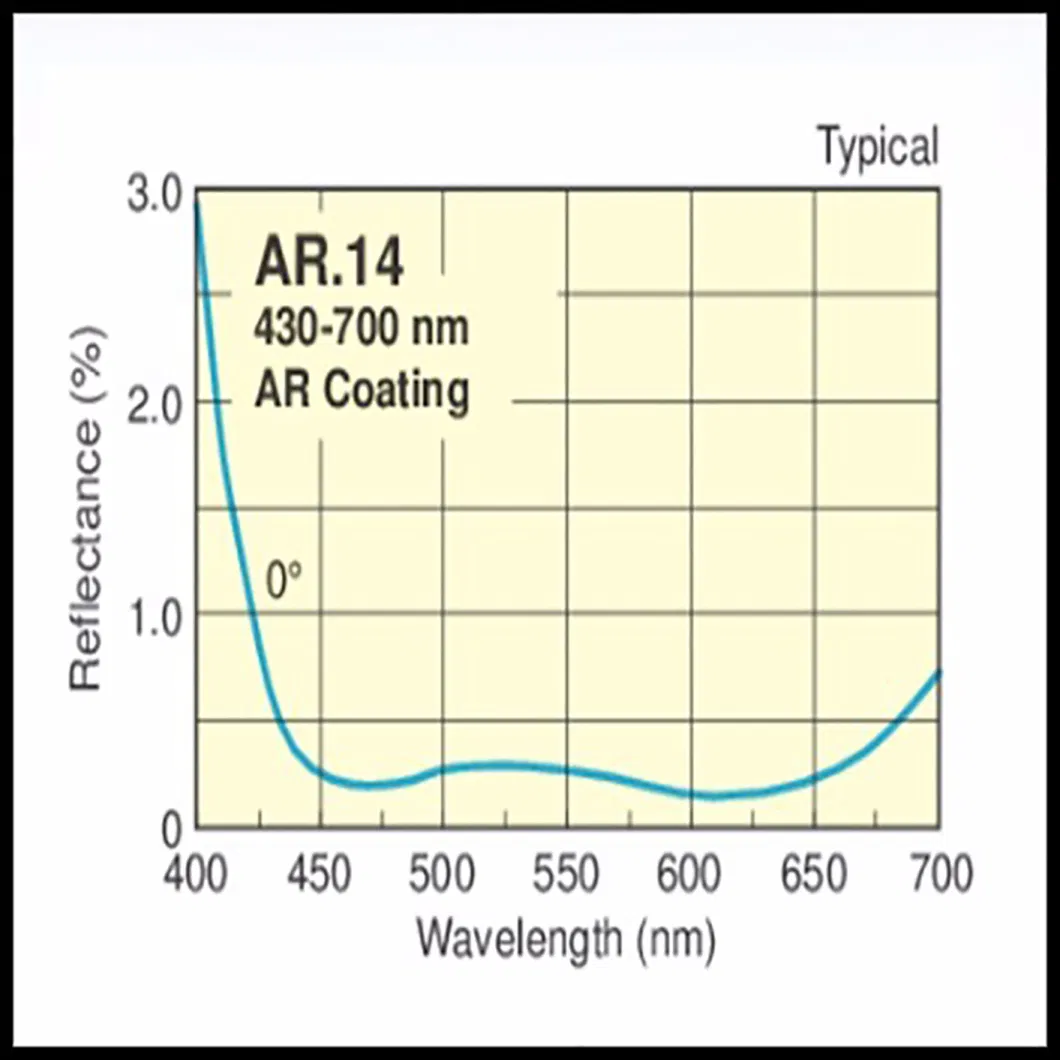

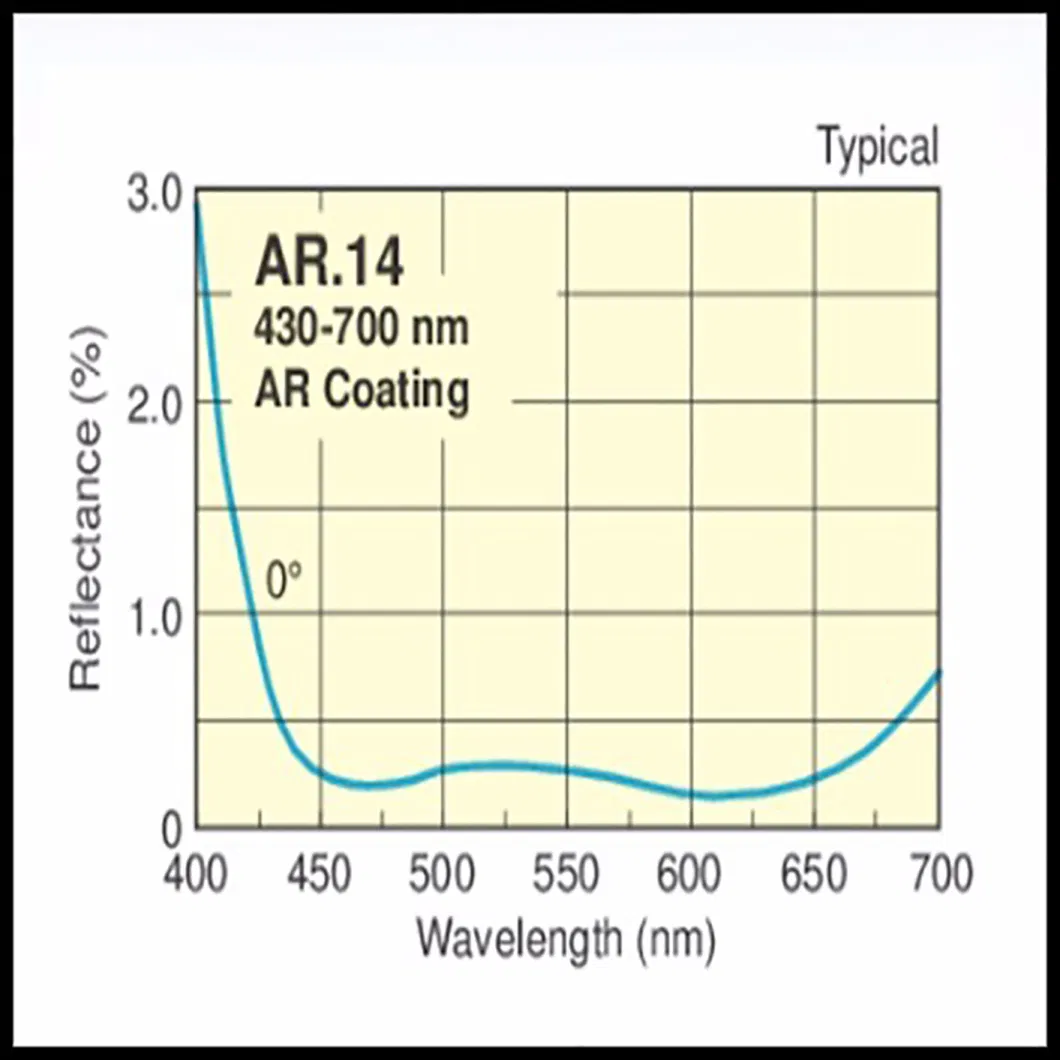

1).Designed Angle of Incidence is 0°

2).Less than 0.4% Reflectance Per Surface at 425 - 675nm

3).Except for MgF2 Coating, VIS 0° & VIS-NIR coated achromatic can also be available

4).High precision & high surface roughness

5).Sizes can be customized as per the customers' request

6).Quick lead time and delivery time.

7).Matching super optics custom and processing capacity, including Moulding, CNC machining, Polishing, Particle beam processing, Magnetic flux conversion processing, Grinding, Coating, Lightweighting, Custom Shaping, Counterbores, Drilling & Coring, Edge & Bevel Polishing,3D Contouring, Bevels & Chamfers, Steps & Slots, Laser Cutting & Marking, Metrology & Inspection, Precision Pitch Polishing, Double-Sided Polishing, Optical Assembly, Measuring, etc.

8).Excellent post-sale quality warranty, with "3R"-return, replace & refund policy

Main Tech Specification:

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy. For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.

Achromatic lens is made by gluing two single lenses. The product is optimized by computer to reduce the spherical aberration and chromatic aberration on the axis. Single layer MgF2 film or broadband antireflection film can be selected. NIR achromatic double glued lens and edge blackening version can also be selected. All dimensions are in mm.

The performance of achromatic lens in multicolor (white light) imaging is much better than that of single lens. This product is glued together by two lenses of different materials (literally "lenses without chromatic aberration") to correct the dispersion of the glass. The achromatic lens is widely used in multi-color lighting and imaging, which improves the cost-effectiveness.

Products Name: VIS Coated Achromatic Lenses

Alias: VIScoating achromatic Lenses, achromatic lens with VIS 0° coating, 4λ achromatic lens, VIS 0° achromatic Lenses

Products Highlights:

1).Designed Angle of Incidence is 0°

2).Less than 0.4% Reflectance Per Surface at 425 - 675nm

3).Except for MgF2 Coating, VIS 0° & VIS-NIR coated achromatic can also be available

4).High precision & high surface roughness

5).Sizes can be customized as per the customers' request

6).Quick lead time and delivery time.

7).Matching super optics custom and processing capacity, including Moulding, CNC machining, Polishing, Particle beam processing, Magnetic flux conversion processing, Grinding, Coating, Lightweighting, Custom Shaping, Counterbores, Drilling & Coring, Edge & Bevel Polishing,3D Contouring, Bevels & Chamfers, Steps & Slots, Laser Cutting & Marking, Metrology & Inspection, Precision Pitch Polishing, Double-Sided Polishing, Optical Assembly, Measuring, etc.

8).Excellent post-sale quality warranty, with "3R"-return, replace & refund policy

Main Tech Specification:

| Universal Optical Tech Data | |

| Optical Lens Type: | Achromatic Lens |

| Focal Length Tolerance (%): | ±2 or custom |

| Focal Length Specification Wavelength (nm): | 587.6 or custom |

| Surface Quality: | 40-20 or custom |

| Coating: | VIS 0°; VIS-NIR; MgF2 Coated Achromats or custom |

| Coating Specification: | Ravg ≤0.4% at 425 - 675nm or custom |

| Power (P-V) @ 632.8nm: | λ/4 or custom |

| Bevel: | Protective bevel as needed |

| Wavelength Range (nm): | 425 - 675 or custom |

| Size/Substrate/Coating Tech Data | |

| Dia. | 2-75mm or custom |

| EFL | 3-750mm or custom |

| BFL | 1.89-746.47 or custom |

| Substrate | N-PSK53A / N-LASF9 N-LAK22 / N-SF6 N-BAF10 / N-SF10 N-BK7 / N-SF5 N-BK7 / N-SF5 N-SSK8 / N-SF56 N-SSK8 / SF56 N-BAF10 / N-SF57 N-SSK8 / N-SF10 N-BK7 / N-SF5 ETC. |

| Coating | VIS 0° coating or custom |

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy. For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.